Tanks

Each tank section may vary from 6M to 7M in height. They each contain LH2, LOX, RP-1, or C2H5OH tanks. Every section uses 4 tanks for the engine flushing system, which are filled with halon, nitrogen, and water. The design of the tank section adds a margin of safety to engine ignition and operation, by using a pressure operated sequence for pumping. Said sequence (patent pending) is akin to a medicine bottle cap which needs to be depressed in the open position. The level of pressure applied for opening or closing, is an indication of the level of temperature rise in the tank.

The propellant load depends on the level of stacking of the tanks. The standard 3-level stacking has around 400+MT of LOX, 50+MT of slush LH2, and 30+MT of Ethanol (C2H5OH) or RP-1. The LH2, LOX, RP-1, and Ethanol pipes are about a quarter of a meter. The 8+-level stacking is for heavy and super-heavy loads, at least 100MT of cargo, which require 800+MT of LOX.

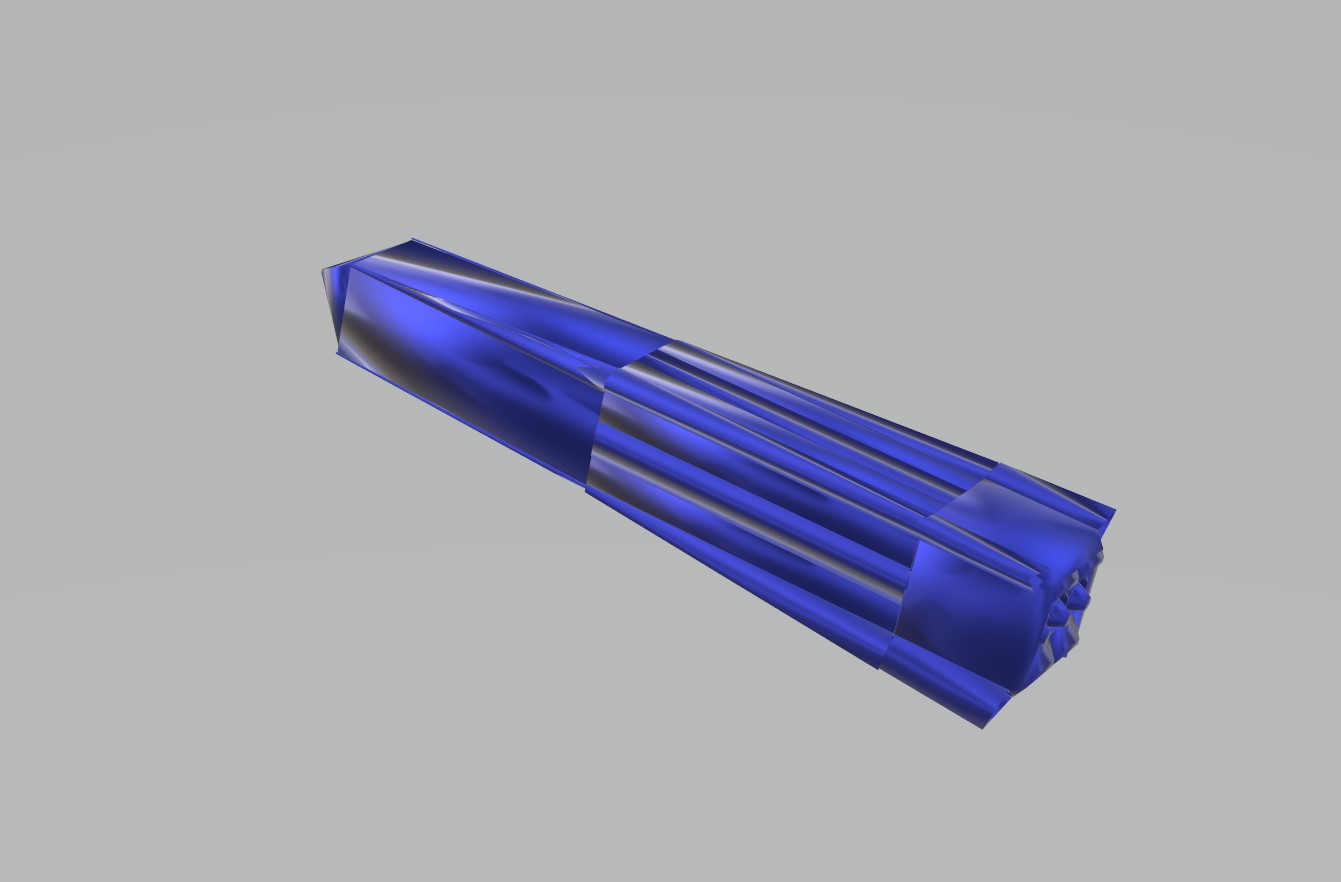

Breezy Clipper©® tanks

Investors welcome !

For more information.